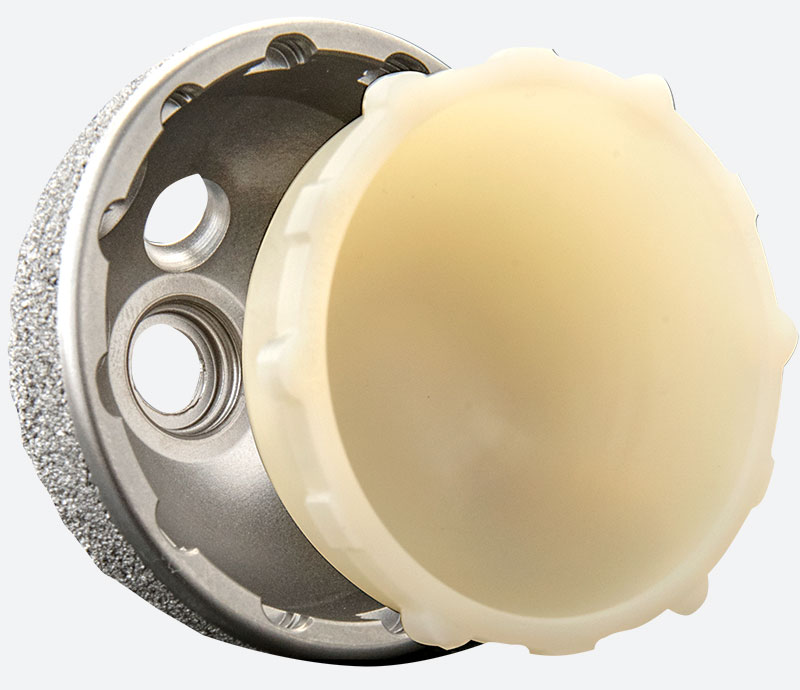

The Advita XLE highly crosslinked vitamin E acetabular liners provide low wear while maintaining mechanical strength, reducing free radicals and oxidative degradation.1

Vitamin E Polyethylene

The XLE liners are manufactured using Ultra High Molecular Weight Polyethylene (UHMWPE) blended with vitamin E prior to consolidation and crosslinking. This provides a uniform distribution of the vitamin E and minimizes the elution effect found in diffused vitamin E liners.1 The gamma crosslinking and annealing process, developed in conjunction with Massachusetts General Hospital, grafts the vitamin E to the polyethylene molecule, resulting in a highly crosslinked material with excellent oxidative stability.3

XLE Vitamin E Liner Features and Benefits

Low Wear

Hip Simulator Wear Rate*

*Test Parameters:

Advita XLE [3]: Test parameters: 40mm diameter CoCr head; 4.4mm thick liner; 5 million cycles; 90% bovine serum; 1.1Hz; 2kN peak load; Wear rate: Slope of the linear regression for corrected mass change in the steady-state cycles

Conventional UHMWPE [2]: Test parameters: Not specified

10Mrd irradiated and melted UHMWPE [2,4]: Test parameters: 46mm head; 3mm thick liner; 11 million cycles; 100% bovine serum; 3.3kN peak load; Wear rate: Slope of the linear regression for corrected mass change over the full number of cycles

10Mrd irradiated, vitamin E diffused UHMWPE [5]: Test parameters: 36mm CoCr head; 4.9mm thick liner; 5 million cycles; 100% bovine serum; 2Hz, 3kN peak load; Wear rate: Slope of the linear regression for corrected mass change over the full number of cycles

Laboratory tests are not necessarily predictive of clinical outcomes

Mechanical Strength

Ultimate Tensile Strength*

*Test Parameters:

Advita XLE [3]: Test parameters: 40mm diameter CoCr head; 4.4mm thick liner; 5 million cycles; 90% bovine serum; 1.1Hz; 2kN peak load; Wear rate: Slope of the linear regression for corrected mass change in the steady-state cycles

Conventional UHMWPE [2]: Test parameters: Not specified

10Mrd irradiated and melted UHMWPE [2,4]: Test parameters: 46mm head; 3mm thick liner; 11 million cycles; 100% bovine serum; 3.3kN peak load; Wear rate: Slope of the linear regression for corrected mass change over the full number of cycles

10Mrd irradiated, vitamin E diffused UHMWPE [5]: Test parameters: 36mm CoCr head; 4.9mm thick liner; 5 million cycles; 100% bovine serum; 2Hz, 3kN peak load; Wear rate: Slope of the linear regression for corrected mass change over the full number of cycles

Laboratory tests are not necessarily predictive of clinical outcomes

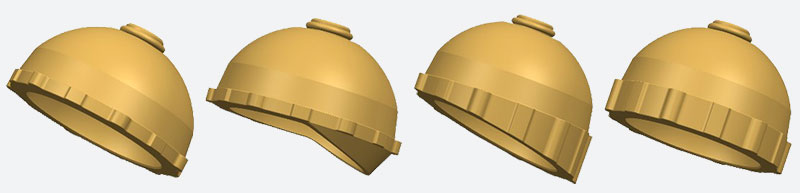

Patented Manufacturing Process

Developed by Massachusetts General Hospital in conjunction with Cambridge Polymer Group.3

Turn compression molded, vitamin E blended UHMWPE to bar stock

10Mrad gamma irradiation

Computer-controlled preheat

Compress 2-1 under heat and cool

Recover at sub-melt temperature

Precision machining

XLE Vitamin E Liner Resources

- Oral, E, Muratoglu, O, “The effects of high dose irradiation on the cross-linking of vitamin E-blended ultrahigh molecular weight polyethylene,” Biomaterials 29 (2008) 3557-3560

- Oral, E, Muratoglu, O, “Vitamin E diffused, highly crosslinked UHMWPE: a review,” Int Orthop. 2011 Feb; 35(2): 215-223

- Data available upon request at Advita.

- Muratoglu OK, Bragdon CR, O’Connor DO, Perinchief RS, Estok DM, Jasty M, Harris WH (2001) Larger diameter femoral heads used in conjunction with a highly cross-linked ultra-high molecular weight polyethylene: A new concept. J Arthroplasty 16(8 Suppl):24 -30

- Oral E, Christensen S, Malhi A, Wannomae K, Muratoglu O (2006) Wear resistance and mechanical properties of highly crosslinked UHMWPE doped with vitamin E. J Arthroplasty 21 (4):580 -591

- Muratoglu OK, Bragdon CR, O’Connor DO, Jasty M, Harris WH,Gul R, McGarry F (1999) Unified wear model for highly crosslinked ultra-high molecular weight polyethylenes (UHMWPE). Biomaterials 20(16):1463 -1470

- Ries M, Pruitt L (2005) Effect of crosslinking on the microstructure and mechanical properties of ultra-high molecular weight polyethylene. Clin Orthop Relat Res 440:149 -156

- Oral E, Wannomae KK, Hawkins NE, Harris WH, Muratoglu OK (2004) a-Tocopherol doped irradiated UHMWPE for high fatigue resistance and low wear. Biomaterials 25(24):5515 -5522

- Bhattacharyya, S, Spiegelberg, S.H, Harris, W.H, Muratoglu, O.K. “Mechanical Elimination of Free Radicals in UHMWPE After Radiation.” 50th Annual Meeting of the Orthopedic Research Society. Paper No: 0184

- Ebru Oral, Bassem W. Ghali, Orhun K. Muratoglu. “The elimination of free radicals in irradiated UHMWPEs with and without vitamin E stabilization by annealing under pressure.” J Biomed Mater Res B Appl Biomater. 2011 Apr;97(1):167-74. doi: 10.1002/jbm.b.31799. Epub 2011 Feb 24

*Laboratory tests are not necessarily predictive of clinical outcomes

These products are manufactured by Exactech, Inc. and distributed by Advita Ortho, LLC.